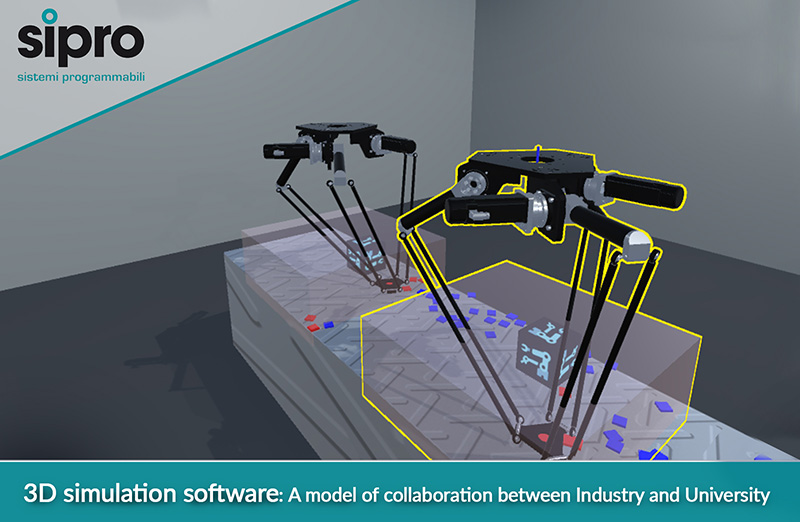

Sipro Delta Simulator (SDS), 3D simulation software: A model of collaboration between Industry and University

Collaboration: The Heart of the SDS Project

Sipro Delta Simulator (SDS) emerges as a brilliant example of collaboration between the industrial and the academic world. This software, jointly developed by Sipro and the University of Verona, marks a turning point in the approach of training and research in the Delta robotics sector. Started in 2021, this multi-year project represents a link between theory and practice, combining Sipro's technical expertise with academic research.

Led by Prof. Riccardo Muradore and developed by doctoral students Nicola Piccinelli and Federico Vesentini, the SDS is a symbol of the joint commitment of Sipro and the University of Verona in carrying out significant research.

The Capabilities of the SDS

SDS is an advanced system that allows you to simulate pick&place applications using one or more robots, while providing precise indications on the workload of each individual station.

It allows you to play applications with one or more conveyor belts, including pick and place areas that can be moving or still.

At the same time, it offers the possibility of defining a random generation of the pieces to be picked up or a well-defined "box" configuration.

This software can simulate the variations of the product’s weight application on the wrist of the robot, showing the existing torques on each individual joint. This allows us to evaluate, also from a dynamic point of view, if it is possible to reach the required speeds without compromising the structural integrity of the robot.

Sipro Delta Simulator also offers the possibility of defining the pick&place times, in order to recreate the waiting times of the grippers.

The SDS environment, developed with Unity platform, is very simple to use and particularly intuitive to manage.

The SDS provides several useful statistics, including the number of products picked per minute, the number of products lost and the average run time of each cycle.

This software allows you to check the feasibility of an application, evaluate the appropriate sizing and verify the maximum achievable performance.

Soon, the SDS simulator will be enriched with the integration for all the robots range provided by Sipro.

Furthermore, the project to connect the SDS software to Sipro SIAX XPC numerical control is under development. This will allow to see on a screen, the machine cycle generated by the developers of the pick&place applications.

Conclusion: A Productive and Training Synergy

Sipro Delta Simulator is an example of the collaboration between company and academic institution and underlines the importance of this synergy. This project looks optimistically to a future in which research and knowledge can be the drives of the evolution in industrial automation.

Back to news

For more information:

Or fill the form to be contacted

Company video

Company video