SIPRO CONTROLS: designed to communicate

One of the milestones of the new paradigm is certainly the possibility of having, in real time, all the relevant information of the production system. The unified and integrated approach to production results in interconnected and intelligent products, plants and resources.

In this context, SIPRO recognized right from the beginning the fundamental importance of developing multiple solutions that facilitate the exchange of information between its systems and the external environment.

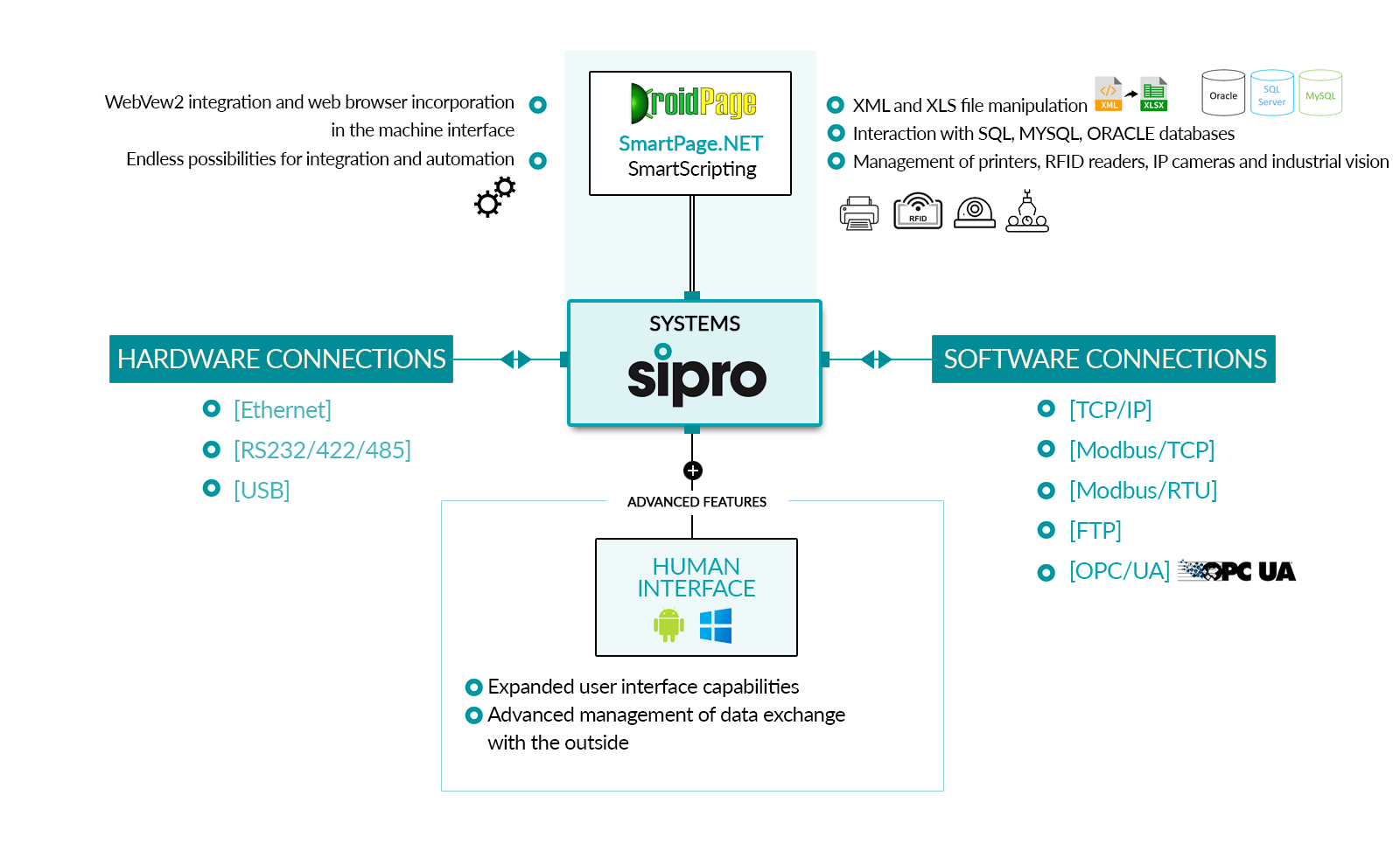

Regarding the hardware connection, all SIPRO systems offer Ethernet and RS232 connectivity for communication, as well as USB for data storage.

Regarding the software, each system is able to communicate via TCP/IP and RS232 with a proprietary protocol or Modbus (TCP/RTU), in FTP protocol (Server via Ethernet connection) and OPC/UA through SiproOPCServer.

To this basic equipment, common to all SIPRO products, advanced features are added when an operator terminal on Android or PC architecture is integrated into the numerical control.

SIPRO HMIS series design and manufacturing operator terminals not only expand the capabilities of the user interface system, but also improve the possibilities of connection with the outside world. Already in the more compact Android terminals of the HMIS series, the possibility of programmatically managing communications on TCP/IP and RS232 sockets allows the development of dedicated communication protocols for any type of external peripheral, both for the collection and transmission of data. Furthermore, the FTP protocol is enriched with client mode, thus allowing the system to send and receive files on the Ethernet network on its own initiative.

In addition to these features, there is a solid set of methods for processing files and data that allows to translate information received from the outside world into data for the operation of the numerical control and the vice-versa.

At the base we find the SmartPage.NET architecture and the SmartScripting programming language, which with a vast set of instructions allows to model at will not only the dynamics of the operator interface, but also the entire communication and data exchange apparatus with the outside world. This includes the management of printers, RFID and barcode readers, measurement and vision systems, the reception and interpretation of production lists, as well as the compilation and sending of production data and diagnostic data.

The full potential of SmartPage.NET and SmartScripting is fully manifested on operator terminals with PC architecture and Windows Operating System. Here, in addition to the functions already present on the systems described, those for manipulating files in XML and XLS format are added. In particular, the implementation of a specific set of instructions that fully exploits the potential of the SQL language allows interaction with SQL, MYSQL and ORACLE databases. This makes a direct, efficient and standardized dialogue with any ERP system possible.

At the same time, the functions for managing system printers, IP cameras and the direct integration of an industrial vision system should be highlighted.

The integration of WebVew2 allows to incorporate a web browser into the machine's dedicated interface, which offers a complete range of features. This allows direct interfacing with any type of web-based management system, closing the data connection loop between the machine and the rest of the world.

SIPRO not only facilitates efficient communication between machines and the external environment but also opens to infinite possibilities for integration and automation.

The flexibility of the connections, together with the ability to manage complex communication protocols highlights SIPRO's commitment towards the creation of a highly interconnected and responsive production ecosystem.

This approach allows companies to not only improve their operational efficiency, but also quickly adapt to changing market needs.

In an era where connectivity and integration between systems represent fundamental bases for business success, SIPRO positions itself as an undisputed leader, driving innovation and setting new standards for the industrial production of the future.

Back to news

For more information:

Or fill the form to be contacted

Company video

Company video